|

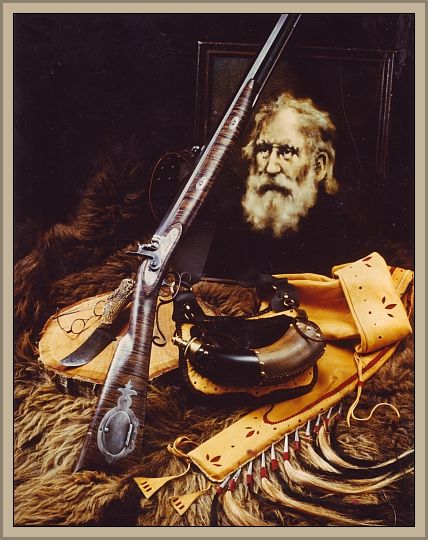

Take a moment, step back in time to the 1800's and visit The Hawken Shop on Washington Street in St, Lois, Mo. The shop is noisy from the throng of workers pounding hammers on their anvils forging springs and forming parts. There are stacks of wood blanks waiting to be shaped Take a moment, step back in time to the 1800's and visit The Hawken Shop on Washington Street in St, Lois, Mo. The shop is noisy from the throng of workers pounding hammers on their anvils forging springs and forming parts. There are stacks of wood blanks waiting to be shaped and inletted for rifle barrels, breeches, tangs, locks and so much more. There is a hustle and bustle of people coming into the shop. Many are here to visit with their peers and discuss the last journey to the wilderness for hides and furs. Some will be talking of the years past rendezvous. Others are there to pick up repaired firearms and traps. And some are coming by to check on the progress of the Hawken rifle they ordered. The same Classic Plains rifles that you will find in today's Hawken Shop. When you get a rifle from the Hawken Shop today of today you will be getting what you would have received from Sam Hawken when he worked his trade on Washington Street. It is still Sam's shop and we are still making Sam's rifle. and inletted for rifle barrels, breeches, tangs, locks and so much more. There is a hustle and bustle of people coming into the shop. Many are here to visit with their peers and discuss the last journey to the wilderness for hides and furs. Some will be talking of the years past rendezvous. Others are there to pick up repaired firearms and traps. And some are coming by to check on the progress of the Hawken rifle they ordered. The same Classic Plains rifles that you will find in today's Hawken Shop. When you get a rifle from the Hawken Shop today of today you will be getting what you would have received from Sam Hawken when he worked his trade on Washington Street. It is still Sam's shop and we are still making Sam's rifle.

The Hawken Shop of 1800's St. Lois didn't have CNC equipment. Each part of a Hawken rifle was hand fit and it still is today. All of our parts have been generated from the real deal. Using the lost wax casting we get parts that are just as the original from which they are cast. Every little imperfection is there now because it was there then. Unlike parts coming from CNC machines where countless pieces can be made to near perfection ours are not. It's not what we are about.

There are some very fine rifles available that have been created using the CNC process. They are near to flawless. There are also kits available stemming from the same technology. These kits are completed to where there is little left to do kits are completed to where there is little left to do

aside from applying the wood and metal

finish. That is in today’s world and it doesn’t have what we are seeking. It is not who we are. We are looking back, striving to connect to yesterday. We want the experience of being in touch with the era where the classic plains rifle was the Pride of the Plains. In its time the Hawken rifle and those who owned them became one. The rifle was a source of protection and a means for obtaining food. For the mountain man it was his life’s blood. Of course not everyone carried a Hawken rifle. Many famous people from the fur trade era didn’t own a Hawken till they were past their prime but they eventually had one. aside from applying the wood and metal

finish. That is in today’s world and it doesn’t have what we are seeking. It is not who we are. We are looking back, striving to connect to yesterday. We want the experience of being in touch with the era where the classic plains rifle was the Pride of the Plains. In its time the Hawken rifle and those who owned them became one. The rifle was a source of protection and a means for obtaining food. For the mountain man it was his life’s blood. Of course not everyone carried a Hawken rifle. Many famous people from the fur trade era didn’t own a Hawken till they were past their prime but they eventually had one.

Our rifles are hand fit and not the product of mass machining. They retain the human element making each one unique unto itself. If you choose to build a rifle yourself you will find a Hawken Shop kit is more time consuming than a CNC kit. You will also discover it puts you, the builder in touch with your gun. The major machining steps have been done. The barrel is breeched, the dove tails for the sights are cut and the trigger group and the lock are assembled.

What is left for you to do is to create a rifle that is distinctly yours. Building your own Hawken rifle is special, it becomes as individual as you, the builder. Once you have the parts married to the wood to your satisfaction the real connection begins. It is your personal attention that now goes into the final shaping of your Hawken rifle. It’s your hand that guides the file perfecting those final touches.

It is you who then takes on the enjoyable task of

sanding your stock and preparing it for a hand rubbed finish. This is a pleasant and rewarding part of the building experience. As you work with the wood you can see the grain showing through, this is true whether it is a stock of modest sanding your stock and preparing it for a hand rubbed finish. This is a pleasant and rewarding part of the building experience. As you work with the wood you can see the grain showing through, this is true whether it is a stock of modest

figure or a heavily striped piece of wood. Whichever it is the oil will bring out the tone and depth of the grain. Like the builder, each stock is unique unto itself with a character all its own. There is no set rule on how many coats of finish you apply. You will be the one to decide, by the look and feel, when your stock is ready. figure or a heavily striped piece of wood. Whichever it is the oil will bring out the tone and depth of the grain. Like the builder, each stock is unique unto itself with a character all its own. There is no set rule on how many coats of finish you apply. You will be the one to decide, by the look and feel, when your stock is ready.

The metal parts, barrel, tang, butt plate and such will need to be finished as well. This is also an exciting part but in a different way. While you see the wood coming alive as you progress the metal doesn’t behave in the same manner.

We recommend browning the metal parts to attain the authenticity of a Hawken rifle. The metal is prepped and the browning solution is applied to the parts and then…you wait. The parts will develop a thin coat of rust. The rust then needs to be carded off and more coats applied. When you feel the parts have a sufficient coverage of rust the magic happens. After the final carding is complete oil is massaged into the rusted surface. You will see an amazing transformation occur as the pieces take on a deep, rich, chocolate brown tone. You are now ready to put wood to metal and admire the Hawken rifle that you have built. Beautiful.

Now a trip to your favorite shooting place to begin a long and pleasant journey of shooting the rifle that you have built. You are ready, your gun is ready, and the time has come. You’ve measured out your powder charge and poured it down the barrel. The patched round ball has been

pushed down the bore and firmly seated onto the powder. The nipple has been capped and now the anticipation of the first shot. The hammer is at full cock, the set trigger is set—you take careful aim as you pull the trigger. The cap goes off, the powder ignites and the ball makes its way down range amid a cloud of smoke. You’ve done it! Like the mountain man of yesteryear you and your Hawken rifle are on the way to becoming one. pushed down the bore and firmly seated onto the powder. The nipple has been capped and now the anticipation of the first shot. The hammer is at full cock, the set trigger is set—you take careful aim as you pull the trigger. The cap goes off, the powder ignites and the ball makes its way down range amid a cloud of smoke. You’ve done it! Like the mountain man of yesteryear you and your Hawken rifle are on the way to becoming one.

A Hawken Shop kit is certainly not for everyone. It will require some time and patience. It is a kit that is for the discriminating shooter who wants to create a rifle that they can take pride in having built themselves. A rifle they can have personal connection to. A Hawken Shop rifle can be a source of enjoyment for you that will extend for generations to come. You can create a family heirloom and be part of preserving a little piece of American history as you do. having built themselves. A rifle they can have personal connection to. A Hawken Shop rifle can be a source of enjoyment for you that will extend for generations to come. You can create a family heirloom and be part of preserving a little piece of American history as you do.

|